1000th 3D Print Patient Treated at Henry Ford Health System

Cardiologists Place New Mitral Heart Valve for Northern Michigan Woman at Henry Ford Hospital

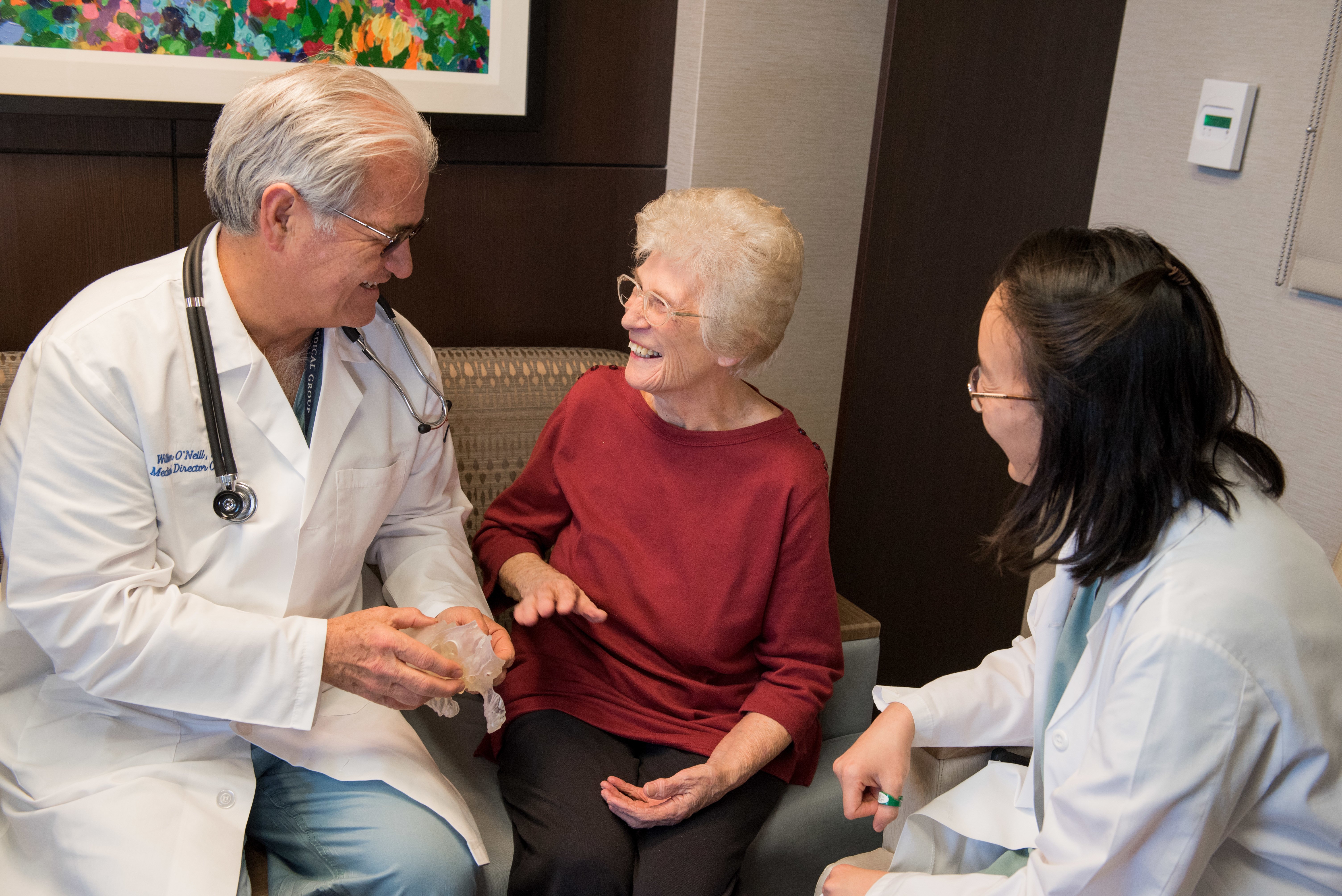

DETROIT — A 72-year-old woman from northern Michigan became Henry Ford Health System’s 1000th patient treated with the aid of 3D printing technology.

Cardiologist Dee Dee Wang, M.D., imaging expert and Medical Director of 3D Printing at Henry Ford Innovations, helped design the print used to position the patient’s new mitral heart valve on March 27.

“When you hold it in your hand it becomes more intuitive rather than just on a screen,” said Dr. Wang. “Our brains understand that better, and that’s invaluable for a surgeon going into a surgery or a cardiologist going into a procedure.”

The 3D model allowed renowned cardiologist Dr. William W. O’Neill, director of the Henry Ford Center for Structural Heart Disease, and his partner, Henry Ford cardiologist Tiberio Frisoli, to ‘see’ inside the patient’s heart before the procedure began. The 3D model assisted with choosing a properly sized valve and knowing how to best position it inside the patient’s heart.

The technology – 3D printing – has been around since the 1980s and is used mostly for industrial manufacturing, research and technology development. Instead of ink to print text or images, 3D printers lay down layer upon layer of plastic or similar materials to build a tangible, physical model.

The procedure guided by Henry Ford’s 1000th 3D print was broadcast live to about 400 interventional cardiologists attending the Scottsdale Interventional Forum in Scottsdale, Arizona.

The U.S. Food and Drug Administration recently commercially approved the use of the Edwards Sapien-3 valve for mitral valve-in-valve replacement. Doctors at Henry Ford Health System, led by Dr. O’Neill, have been using the valve in this application for about five years, with the aid of 3D printing.

“The most important part is the planning,” said Dr. O’Neill, “There’s integral planning that’s involved with sizing the valve, assuring that the positioning is accurate and there is no potential for obstruction of blood flow within the heart. The procedure is amazing. And with the aid of 3D printing, it is incredibly effective and very safe with the proper planning. And we’ve become a leader in medical 3D printing, thanks to Dr. Wang and Henry Ford Innovations.”

In addition to cardiology, Henry Ford Health System uses 3D printing for vascular aneurysm planning, oncology planning, cranial-facial reconstruction and orthopedics at Henry Ford, said Eric Myers, Product Designer and Technical Director for 3D Printing at Henry Ford Innovations. Marianne Rollet, Imaging Operations Coordinator at Henry Ford’s Center for Structural Heart Disease, uses computer programs and two-dimensional, black and white CT scans to guide 3D printers to create 3D models made of light-sensitive polymers.

“It provides the doctors a whole new level of understanding of the intricacies and details within the body,” Eric said. “Dr. Wang and I developed this program five years ago, and now we’re at the 1000th patient. I’m very proud of that. I’m so glad we’ve been able to help so many people.”

Henry Ford’s 1000th 3D Print patient, Lillian Keavey, was referred by Alpena, Michigan, cardiologist Dr. Abraham Salacata. She had been experiencing shortness of breath and decreased stamina. The symptoms led to her diagnosis of mitral valve stenosis – and the need for a new mitral valve.

“I was very glad to be chosen to have it done because the alternative was another open heart surgery, and I wasn’t looking forward to that,” said Lilian. “There’s a three-month recovery, whereas this one is just two weeks. It’s fascinating, looking at that heart (model).”

Lillian said she is most looking forward to resuming daily walks with her daughter and her daughter’s dog, Jojo. They’ve walked every day for years, except when it is under -10 degrees – so Jojo’s paws don’t get too cold.

“She’s 9 years old, and we’ve walked her every morning,” Lillian said. “So I’m looking forward to getting back to the things I normally do.”

###

Media contact: Tammy Battaglia / Tbattag1@hfhs.org / 248-881-0809

.svg?iar=0&hash=F6049510E33E4E6D8196C26CCC0A64A4)

/hfh-logo-main--white.svg?iar=0&hash=ED491CBFADFB7670FAE94559C98D7798)